RPC supports NSW WaterAid Golf Day on December 1, 2020

WaterAid Golf Day NSW 2020 RPC is proud to support NSW WaterAid in its work to raise funds for the world’s most marginalised

WaterAid Golf Day NSW 2020 RPC is proud to support NSW WaterAid in its work to raise funds for the world’s most marginalised

COVID-19 UPDATE FOR CUSTOMERS & SUPPLIERS

RPC’s Corio facility turned 10-years-old recently. Here’s a great news story about this landmark for us and our friends, Bisinella Developments, published by

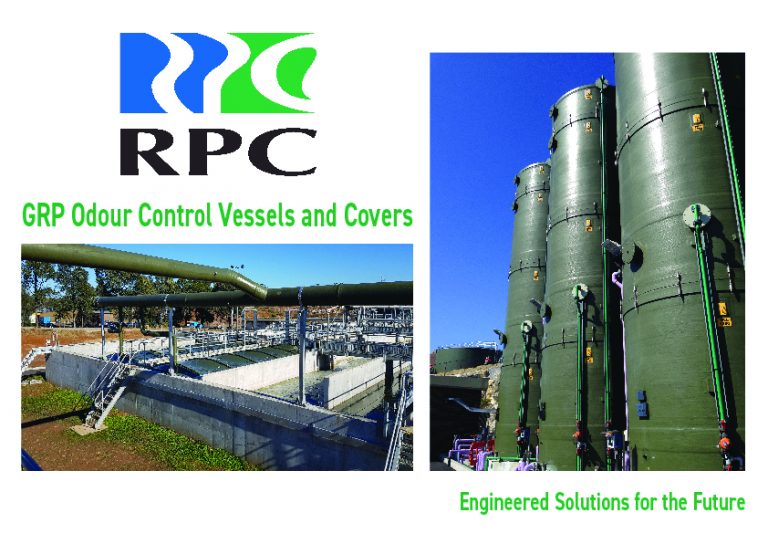

RPC’s Glass Reinforced Polymer (GRP) Vent Shafts – Perma Vent™ are chemically and structurally engineered with the optimal balance of resin and glass

RPC is proud to celebrate 10 successful years of operations in Geelong, Victoria, underlining our commitment to manufacturing in Australia and providing employment

COVID19 Customers June 4 2020 R

RPC designed, manufactured, delivered and installed this 20m self-supporting GRP tank cover for Icon Water’s upgrade of the Lower Molonglo Wastewater Treatment Plant

COVID 19 UPDATE – 6 May 2020 – Customer Letter

CEO Customer letter 2 COVID-19

MARCH 2020: RPC has purchased and installed the latest technology in 3D Scanning Systems in the Batam, Indonesia facility. The system is totally

Due to the ongoing drought, the subject of moving water to areas in critical need such as the Queensland township of Stanthorpe is

RPC is pleased to advise we have gained accreditation as part of the Defence Industry Security Program (DISP). DISP strengthens Defence security practices

Following RPC Technologies success in implementing one of #thebestrun SAP S/4Hana Cloud implementations in the APAC region, this week Keith Pattison, Tony Caristo

RPC Technologies has been awarded the prestigious 2019 SAP Best Run Award for Australia & NZ in the category of Data & Analytics at SAP’s annual industry awards event at Sydney’s Museum of Contemporary Art.

Continuing to successfully deliver complex infrastructure in the water sector, RPC Technologies is proud to announce we have been successful in securing the

RPC Technologies MD, Tony Caristo, will be the first speaker at the Composites Australia annual conference kicking off tomorrow morning at the Kirribilli

We are excited to announce the launch of our newly designed website for RPC Pipe Systems www.rpcpipesystems.com. Our goal with this new website

Virginie Murphy, Engineering Manager from our Newcastle office, recently visited Tods Defence in the UK where she met with Simon Francis, Pete Eckersall,

RPC is pleased to announce the signing of a three-year license bringing the UTComp’s UltraAnalytix™ technology to Australia, New Zealand and South East

The third lot of 6,500m of 1.8 metre diameter Flowtite® GRP pipes has arrived in Townsville from our RPC Pipe Systems plant in

Indonesia:This week, RPC successfully completed Stage 1 Hydrostatic testing of 2.4m Diameter GRP cooling water pipe for the Tambak Lorok Combined Cycle Power

The Palaszczuk Government’s accelerated $225 million funding for Townsville’s Haughton Pipeline Duplication Project is creating hundreds of local jobs, boosting advanced manufacturing and

RPC Pipe Systems in Lonsdale welcomed a visit on December 19 from the SA Minister for Industry and Skills, David Pisoni MP, and

RPC Indonesia has been working closely with Australia’s premium luxury motor yacht builder, Riviera Australia Pty Ltd, over the last 4 years. We

This is the body text for the issues being experienced at this location